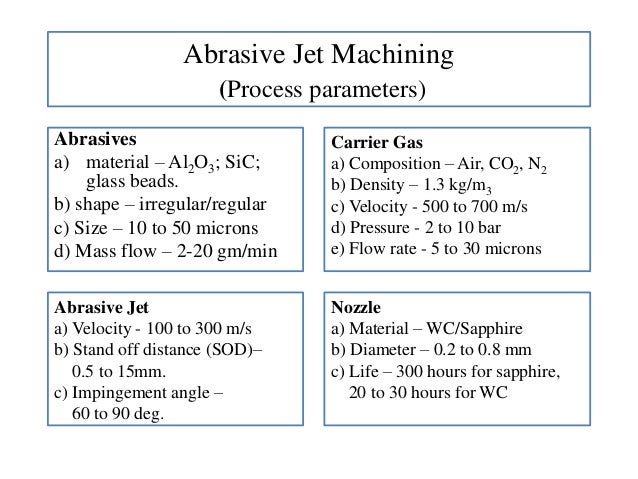

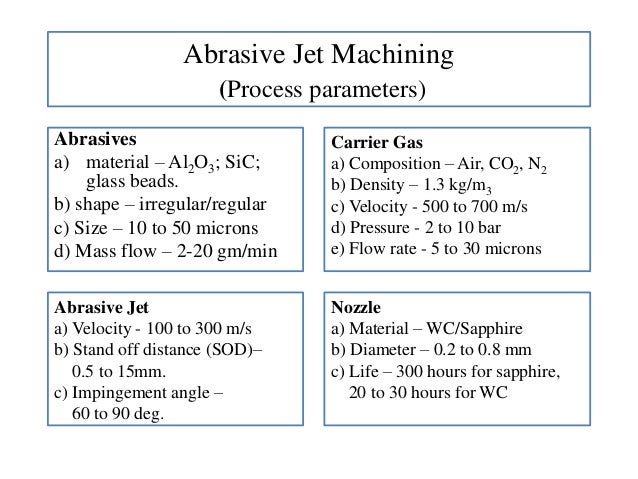

Air Abrasive Jet Machining Is A Non-traditional Machining Process In Which A High Pressure Air Stream And Abrasive Particles Are Impinged On A Work Surface Through A Nozzle. A Model Of Ajm Was Designed, Developed And Fabricated To Perform Experimentation. In This Paper Drilling Work Is Done On Glass Work Piece And Silicon Carbide (Sic) As Abrasive Powder.

The Air Pressure, Abrasive Size And Nozzle Tip Distance Are Considered As Controlling Parameter. The L18 Orthogonal Array Based On Taguchi Method Of Design Of Experiment Is Selected Based On Different Levels Of Controlling Parameters. The Effect Of Each Controlling Parameter On Material Removal Rate (Mrr) And Taper Angle Is Analyzed By Using Analysis Of Variance(Anova) And Graphs Are Plotted

No comments:

Post a Comment